HANGZHOU NUZHUO TECHNOLOGY GROUP CO., LTD.

NUZHUO Tuam Tshoj Cryogenic Oxygen Cog Rau Steel Smelting High Purity 99.6% Kua Oxygen Metallurgical Cog

Cov Lus Qhia:

| Lub Npe Khoom | Cov khoom siv sib cais cua cryogenic |

| Qauv No. | NZDON- 50/60/80/100/120KHOOM SIV RAU KOJ TUS KHEEJ |

| Hom | NuZhuo |

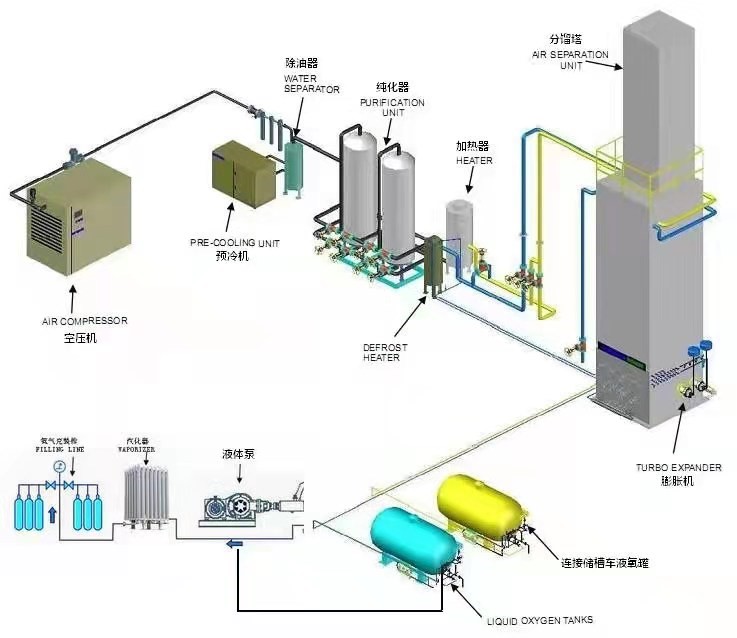

| Cov Khoom Siv | Cua compressor & Re-cooling system & Expander & Txias lub thawv |

| Kev Siv | Tshuab tsim cov pa oxygen & Nitrogen & Argon purity siab |

Cov txheej txheem tsim cov pa oxygen cryogenic & cov txheej txheem tsim cov pa oxygen & nitrogen qhia txog cov txheej txheem qis-siab rau hauv cov khoom siv sib cais huab cua, uas txo cov kev siv hluav taws xob ntawm kev sib cais huab cua thiab txhim kho kev nyab xeeb ntawm kev ua haujlwm. Cov software tshuaj sib xws yog siv rau hauv kev suav cov txheej txheem thiab cov khoom siv tsim rau kev suav cov txheej txheem distillation thiab kev suav cov qauv kom ntseeg tau tias cov khoom siv siab heev thiab txhim khu kev qha.

Yuav kom ua tau raws li qhov xav tau ntawm kev ua lag luam, ntxiv rau kev tsim cov khoom siv sib cais cua sab nraud, lub tuam txhab kuj tau tsim cov txheej txheem sib cais cua sab hauv, uas txo cov haujlwm teeb tsa thiab kev saib xyuas cov khoom siv ntawm cov khoom siv tiav.

Lub tuam txhab tau tsim thiab tsim ib lub tshuab ntxuav dej uas muaj skid-mounted kom txo lub sijhawm teeb tsa cov kav dej hauv qhov chaw.

| Qauv | NZDON-50/50 | NZDON-80/160 | NZDON-180/300 | NZDON-260/500 | NZDON-350/700 | NZDON-550/1000 | NZDON-750/1500 | NZDON-1200/2000/0y |

| O2 0 tso zis (Nm3 / h) | 50 | 80 | 180 | 260 | 350 | 550 | 750 | 1200 |

| O2 Kev Huv Si (% O2) | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 |

| N2 0 tso zis (Nm3 / h) | 50 | 160 | 300 | 500 | 700 | 1000 | 1500 xyoo | 2000 xyoo |

| N2 Qhov Huv Si (PPm O2) | 9.5 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Cov kua Argon tawm (Nm3/teev) | —— | —— | —— | —— | —— | —— | —— | 30 |

| Cov kua Argon Purity ( Ppm O2 + PPm N2) | —— | —— | —— | —— | —— | —— | —— | ≤1.5ppmO2 + 4 pp mN2 |

| Cov kua Argon Purity ( Ppm O2 + PPm N2) | —— | —— | —— | —— | —— | —— | —— | 0.2 |

| Kev siv nyiaj (Kwh/Nm3 O2) | ≤1.3 | ≤0.85 | ≤0.68 | ≤0.68 | ≤0.65 | ≤0.65 | ≤0.63 | ≤0.55 |

| Thaj Chaw Nyob (m3) | 145 | 150 | 160 | 180 | 250 | 420 | 450 | 800 |

Lub luag haujlwm ntawm cov thev naus laus zis cryogenic hauv kev smelting hlau:

Kev siv oxygen hauv kev lag luam tseem ceeb yog kev txhawb nqa kev sib xyaw. Ntau yam khoom siv uas feem ntau tsis sib xyaw hauv huab cua tuaj yeem sib xyaw hauv oxygen, yog li kev sib xyaw oxygen nrog huab cua ua rau kev sib xyaw ua ke zoo dua hauv kev lag luam hlau, tsis yog ferrous, iav thiab pob zeb. Thaum sib xyaw nrog roj roj, nws siv dav hauv kev txiav, vuam, brazing thiab tshuab iav, muab qhov kub siab dua li kev sib xyaw hauv huab cua, yog li txhim kho kev ua haujlwm. Nrog rau cov txheej txheem oxyfuel, plasma thiab laser, cov pa oxygen tuaj yeem siv los txiav hlau. Oxygen kuj tseem siv rau kev khawb kub lossis txiav cov ntaub ntawv xws li pob zeb, cib, pob zeb thiab ntau yam hlau.

Cov Ntaub Ntawv Txog Lub Tuam Txhab

Daim Ntawv Pov Thawj & NUZHUO

Q1: Koj puas yog lub tuam txhab lag luam lossis chaw tsim khoom?

Q3: Koj lub sijhawm xa khoom ntev npaum li cas?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: Koj txoj cai pov thawj khoom zoo yog dab tsi?

Q5: Koj puas muab kev pabcuam OEM / ODM?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Koj cov khoom puas siv los yog tshiab? RTS khoom lossis customized khoom?

Pawg Khoom

Tsom ntsoov rau kev muab cov kev daws teeb meem mong pu rau 5 xyoos.

Xov tooj: 0086-15531448603

Xov tooj: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com